Understanding Fume Cupboard Testing in Newport

In the heart of Newport, where innovation and safety go hand in hand, fume cupboard testing emerges as a crucial aspect of laboratory management. Ensuring the optimal performance of fume cupboards not only complies with legal requirements but also protects personnel from hazardous substances. This comprehensive guide delves into the importance, procedures, and benefits of fume cupboard testing, and why choosing the right service provider is critical for your business.

What is a Fume Cupboard?

A fume cupboard, also known as a fume hood, is a ventilated enclosure that captures harmful fumes, vapors, and particles generated during laboratory processes. It acts as a primary safety barrier, minimizing the exposure of laboratory personnel to toxic chemicals.

Key Functions of a Fume Cupboard

- Protection: Shields users from hazardous substances.

- Ventilation: Ensures proper airflow to dilute and remove harmful air contaminants.

- Containment: Prevents the spread of spills or chemical reactions beyond the work area.

- Kimberly-Clark Compliance: Adheres to local and international safety standards.

Why is Fume Cupboard Testing Important?

Regular testing and maintenance of fume cupboards are paramount to ensure they function correctly. Here's why fume cupboard testing is critical for your laboratory:

1. Health and Safety Compliance

Following regulatory frameworks, such as the Health and Safety at Work Act and COSHH (Control of Substances Hazardous to Health), is vital. Regular testing can help ensure compliance with these regulations, protecting both staff and organization from legal repercussions.

2. Performance Verification

Testing verifies the *performance* of your fume hoods, checking airflow velocity and ensuring they operate within *safe limits*. This process helps maintain trust in the laboratory's safety protocols.

3. Preventative Maintenance

Routine testing can identify issues before they become critical. Early detection of problems means you can take necessary actions, avoiding costly downtime and repairs.

4. Research Integrity

In research environments, results must be reliable and reproducible. Ensuring that fume cupboards are functioning optimally helps maintain the integrity of scientific research.

Fume Cupboard Testing Procedures

The following steps outline the typical procedure for conducting fume cupboard testing:

Step 1: Visual Inspection

The initial step involves a thorough visual inspection of the fume cupboard for any obvious defects such as broken glass panels, incorrect sash height, and obstruction of air inlets.

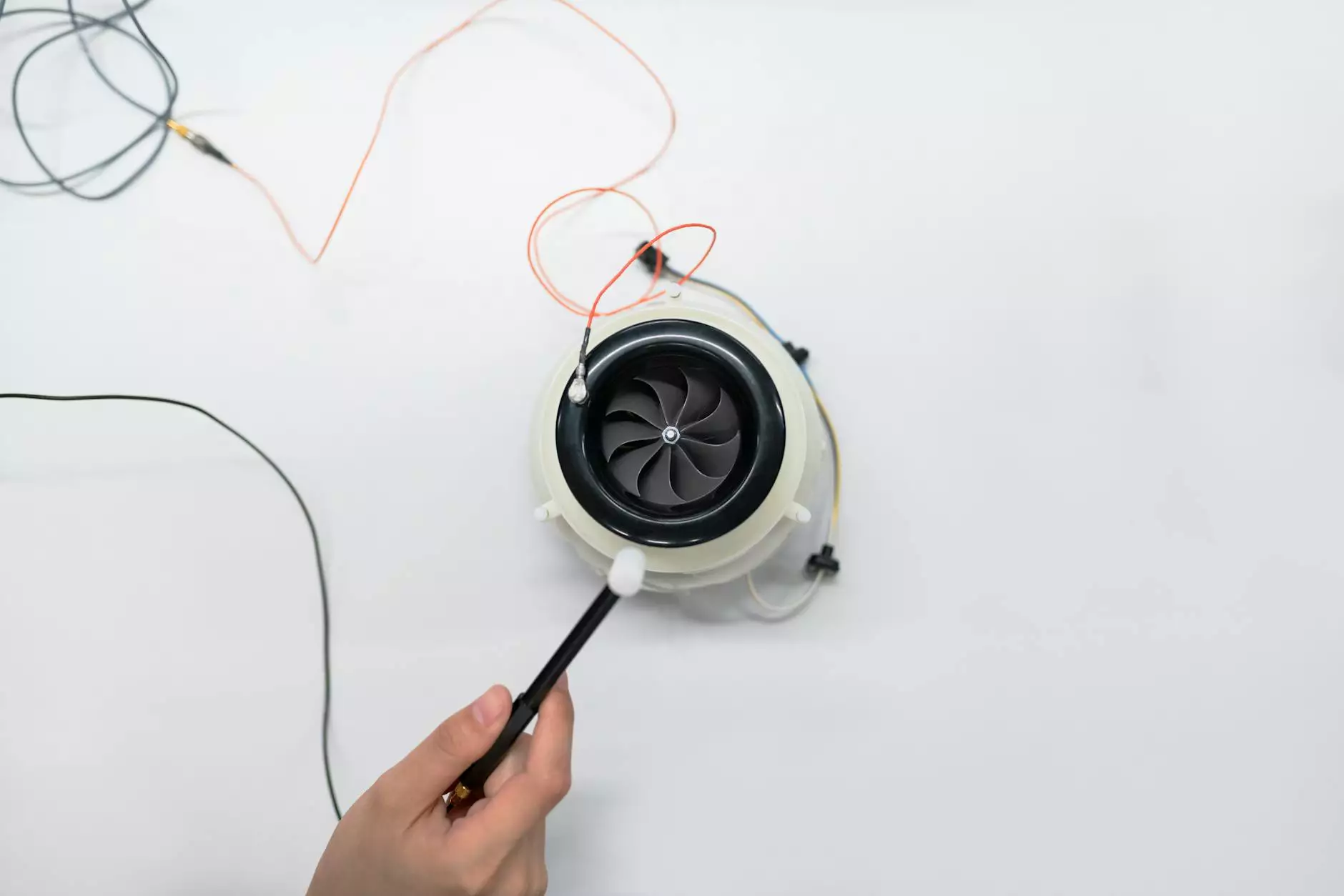

Step 2: Airflow Measurement

Using specialized instruments, technicians will measure the airflow velocity within the fume cupboard. The standard airflow velocity should be between 0.5 and 1.0 meters per second.

Step 3: Sash Operation Check

The sash should operate smoothly, and its position should be checked. A properly functioning sash helps maintain optimal airflow and containment.

Step 4: Filter Assessment

For fume cupboards equipped with filters, their condition must be evaluated. Filters should be replaced regularly to ensure efficiency.

Step 5: Documentation

Finally, results from the testing are documented. This documentation is vital not only for compliance but also for future reference and maintenance cycles.

Choosing a Fume Cupboard Testing Provider in Newport

Selecting the right service provider for fume cupboard testing in Newport is critical. Here are some tips to make the best choice:

1. Experience and Expertise

Choose a company with proven experience in the field. Their knowledge of local regulations and best practices in fume cupboard maintenance is essential.

2. Accreditations

Verify that the provider holds relevant certifications that validate their competence and adherence to safety standards.

3. Service Range

Look for a provider that offers comprehensive services, including repairs, filter replacements, and emergency services. They should cater to your specific needs and laboratory requirements.

4. Customer Reviews

Check online reviews and testimonials to gauge customer satisfaction and reliability of the service provider.

The Benefits of Regular Fume Cupboard Testing

Regular fume cupboard testing yields numerous benefits:

Enhanced Safety

Keeping air quality high and reducing exposure to hazardous materials allows laboratories to maintain a safer working environment.

Increased Efficiency

Well-maintained fume cupboards operate more efficiently, which ultimately saves costs associated with energy usage and accidental spills.

Regulatory Compliance

Regular testing ensures adherence to local and national safety standards, avoiding fines and ensuring the integrity of your operations.

Conclusion: Fume Cupboard Testing - A Necessity for Safe Operations

Fume cupboard testing is not merely a regulatory requirement; it is a pivotal aspect of ensuring a safe and productive laboratory environment. Businesses in Newport and beyond should prioritize this essential facet of occupational health and safety management. Partnering with a reliable testing provider can help mitigate risks and enhance the overall safety culture within your organization.

At Safe Plant UK, we are committed to providing exceptional fume cupboard testing services tailored to your specific needs. Contact us today to ensure your laboratory is fully compliant and safe!

fume cupboard testing newport